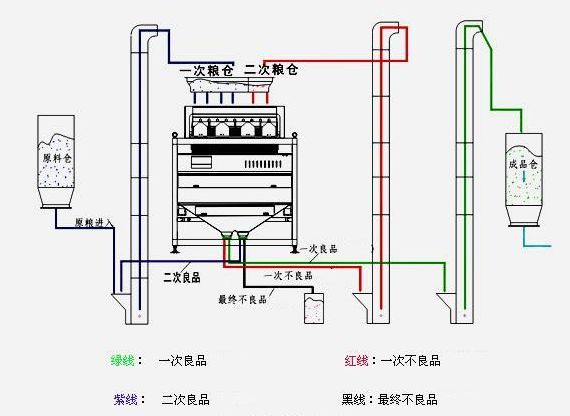

Colour sorter-intelligent product with eyes, among which the photoelectric detection part is called "eye". In this part, there are cameras and sensors, which can shoot clearly and inject the bad products through high frequency solenoid valve to achieve the optimal effect. Its function is ten thousand times stronger than that of human eyes. Colleagues'color sorter passes through this "eye". Eye"simply and quickly screens out the bad products, impurities and heterochromatic particles in the products, and obtains the products of high quality, which makes the profits of the producers soar, and receives the praise of the vast number of customers. The working principle and working procedure of color sorter are explained in detail. 1. Connect the power supply, turn on the tablet computer and touch the touch screen lightly to start the color sorting work. 2. Then put the material ready for color sorting into the vibrating feeding hopper, and through the high frequency jitter of the feeder, the material jitter falls into the material distribution trough. 3. When the material falls into the sorting box, the front and back of the two megapixels. Cameras will take high-frequency comprehensive photographs of each material, no lethal angle 4. Photographs taken will be compared with qualified materials through spectral analysis. Material with different colors and inconsistent with qualified products will be found. Air valves will blow out the unqualified materials into the overflow outlet, while qualified materials will be along the overflow outlet. Set the route to the qualified outlet.